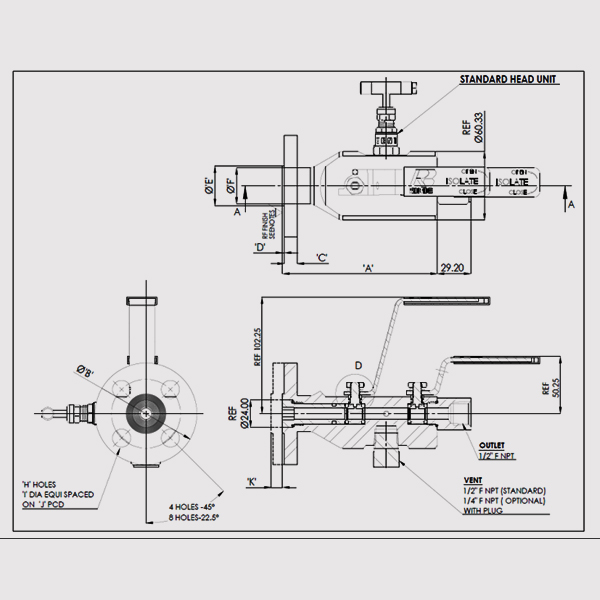

DOUBLE BLOCK & BLEED VALVE

Category: Double Block and Bleed Valves

| Features |

Features of the Product

• Flange construction as per Std ANSI B16.5 std • Design & Pressure rating as per std ASME B16.34 std • NPT Threads as per std ANSI B1.20.1 • Low operating torque • Bubble tight shut off • Compact design for instrumentation • Floating type soft seated ball valve • Self cavity relief seat design • Locking kit (Optional ) • Firesafe design option available as per STD API 607 / ISO 10497 Features of Needle Valve Vent • Re adjustable packing method increase packing life • Metal to metal seat for bubble tight positive shut off • Metal back seat to avoid stem blow out during operation and reduce packing stress during full open condition • Packing below thread to avoid lubricant washout • Non rotating Tip for long life and self-centering • Dust cap to protect from contamination • Supply to NACE MR 0175 / ISO15156, if required • Anti tamper key (Optional ) • Bleeder plug as an option for vent plug |

|---|---|

| ANSI Pressure class |

150# / 300# / 600# / 900# / 1500# / 2500#

|

| Size |

1/2" to 3” ( DN 15 to DN 80 )

|

| Bore size |

10MM , 13MM, 14MM, 19MM ,25MM

|

| Materials |

SS 316/316L , A105 / 350LF2, MONEL, INCONEL, DUPLEX, SUPER DUPLEX, HASTELLOY

|

| Gland packing |

PTFE / RPTFE / GRAPHITE

|

| Seat |

PTFE / RPTFE / DEVLON / PVDF / PEEK / CF PTFE / METAL TO METAL

|

| Working Temperature |

-29°C To +250°C ( -20.2°F To +482°F)

|

| Testing |

100% Hydro testing performed as per Std BS EN 12266-1 / API 598

|

| Inlet |

Flanged end (RF / RTJ)

|

| Outlet |

Flanged end ( RF / RTJ ) or Screwed end ( NPT )

|

| Vent |

1/2" (or) 1/4” NPT / BSPP / BSPT

|