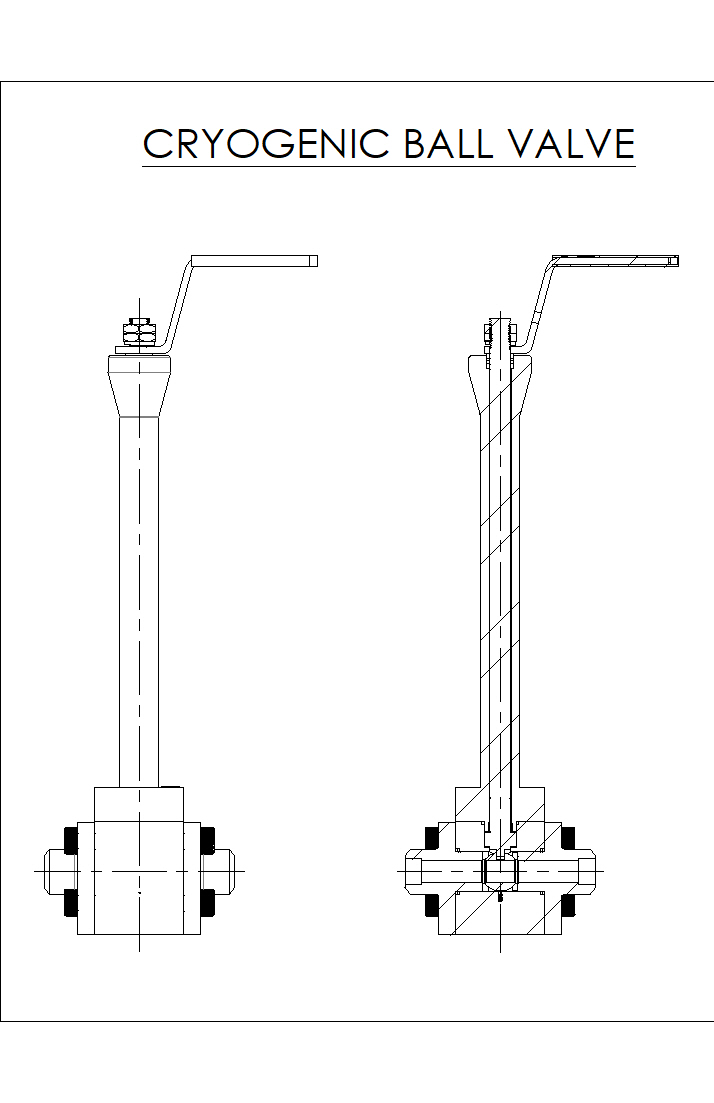

CRYOGENIC BALL VALVES

Category: Cryogenic Valves

| Features |

• Compact design

• Suitable to work upto -196°C • Flexible Two/ Three piece design • Flanged end as per std ASME B16.5 • Butt weld end as per std ASME B16.25 • NPT Threads as per std ANSI Std B1.20.1 • Socket weld end as per std ASME B16.11 • Design & Testing as per std BS 6364:1984 • Welding process qualified to ASME BVPC SEC IX • Stainless Steel construction with extended Bonnet Type • Floating type soft seated self energized ball valve • Bubble tight positive shut off • Low operating torque • Metal back seat to avoid stem blowout during operation |

|---|---|

| Size |

1/2” to 2” ( DN10 To DN50 )

|

| Materials |

ASTM A182 / A479 - SS 316 / 316L

|

| Gland packing |

PTFE / PCTFE (KEL-F) / GRAPHITE

|

| Seat |

PCTFE (KEL-F) / PTFE

|

| Working Temperature |

-196°C to +95°C ( -320.8°F To +203°F )

|

| Testing |

• 100% Hydro testing performed as per Std BS EN 12266-1

• Cryogenic Testing @ -196°C as per std BS6364:1984 • 3rd Party approval option available |

| Ansi Class |

ANSI Class: 150# / 300# /600# / 800# / 900# / 1500# / 2500#

|

| Inlet |

Flanged end / Butt Welded end / Screwed end / Socket Welded end

|

| Outlet |

Flanged end / Butt Welded end / Screwed end / Socket Welded end

|

| Certification |

EN10204 – 3.1 Certification as standard / 3.2 if required

|