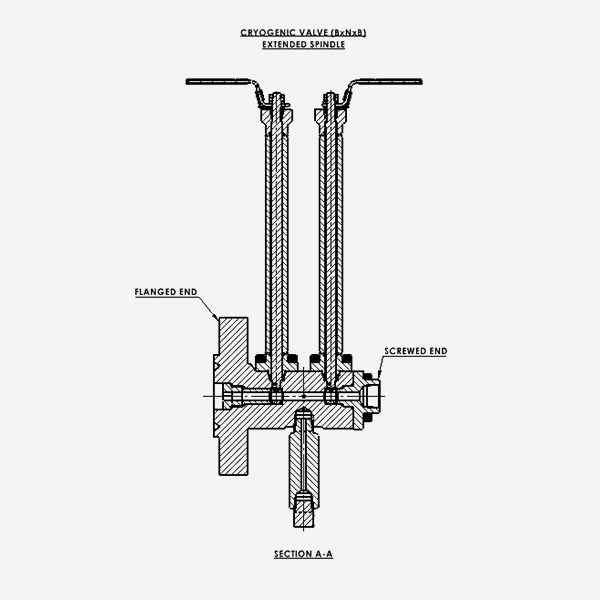

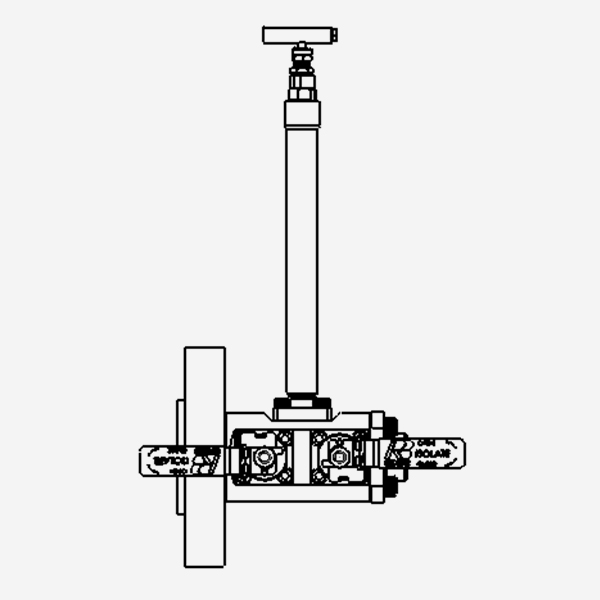

CRYOGENIC DOUBLE BLOCK AND BLEED VALVES

Category: Cryogenic Valves

| Features |

Features of the Product

• Compact design / Suitable for service upto -196°c • Design and Testing as per BS 6364:1984 standard • Welding qualification to BVPC sec IX , if applicable • Extended Bonnet design to safeguard packing from medium temperature • Low operating Torque • Re-adjustable packing method for long life Features of Needle Valve Vent • Non rotating tip for long life and self centering • Metal to metal seat for positive shut off • Metal back seat to avoid stem blow out during operating and reduce stress during full open condition |

|---|---|

| ANSI Pressure class |

ASME 150#/300#/600#/900#/1500#/2500#

|

| Size |

¼” to 2” (DN 8 to DN 50)

|

| Materials |

SS316/316L, Monel, Inconel, Hastelloy

|

| Seat |

PTFE/PCTFE(KEL-F)

|

| Working Pressure |

Upto -196°c to +180°c (-320 °F to +356°F)

|

| Testing |

• 100% hydro testing performed as per std BS EN 12266-1/API 598

• Cryogenic testing @-196°c as per std BS6364:1984 • 3rd party approval option available if required |

| Inlet |

Flanged end (RF/RTJ)/Screwed end NPT/Weld Ends

|

| Outlet |

Flanged end (RF/RTJ)/Screwed end NPT/Weld Ends

|

| Packing |

PTFE/PCTFE(KEL-F)/ Graphite

|

| Vent |

Screwed end NPT

|

| Certification |

EN10204 – 3.1 Certification as standard / 3.2 if required

|